Leading Jaw Crusher Manufacturer

Precision in Every Product, Excellence in Every Service.

Welcome to K. S. Jandu & Sons

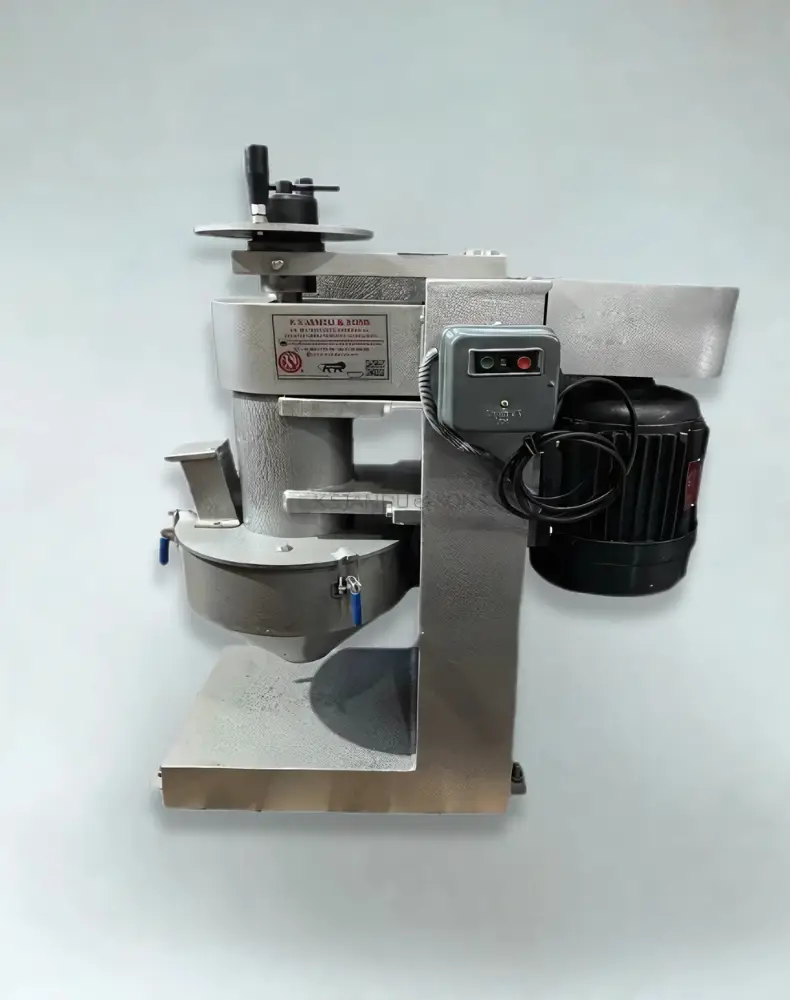

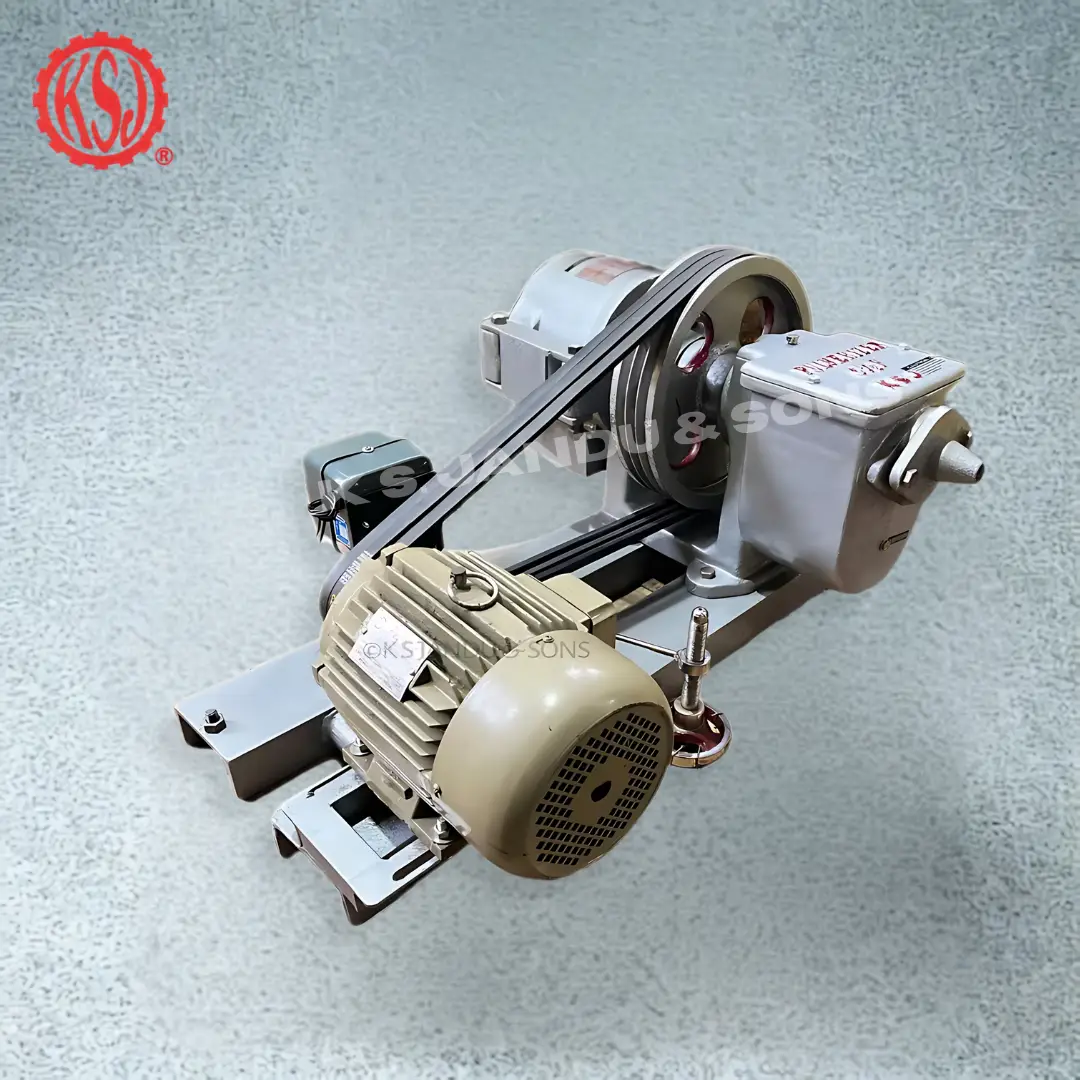

Founded in 2011, K. S. Jandu & Sons is a trusted name in manufacturing, exporting, and trading high-performance Industrial and Laboratory equipment. From Sieve Shakers and Laboratory Pulverizers to Laboratory Jaw Crushers, Laboratory Ball Mills, and Planetary Mixers, we deliver durable, precision-engineered machinery built to meet the needs of construction, research, and industrial sectors.

With a strong focus on innovation, quality craftsmanship, and timely delivery, we serve various industries across India and globally. Our state-of-the-art infrastructure, skilled workforce, and customer-first approach allow us to offer customised solutions at competitive prices.

Whether you need accurate material testing machines, efficient mixing systems, or sample preparation tools, K. S. Jandu & Sons is your ideal partner for reliability and results.

Our Categories

Largest Laboratory Jaw Crusher Manufacturing in India

+91-97119 86384

For More Details Contact Us Now!

Our Products

Why Choose K. S. Jandu & Sons?

At K. S. Jandu & Sons, we don’t just deliver machines — we deliver trust, performance, and precision. Here’s why businesses across India and around the world choose us as their preferred partner

Industry Experience

With over a decade of proven expertise since 2011, we understand the evolving demands of industrial and laboratory applications.

Superior Quality & Engineering

Our equipment is built with precision and durability in mind, using premium materials and cutting-edge manufacturing practices to ensure consistent performance.

Tailored Solutions

Every client’s requirement is unique — and so is our approach. We specialize in offering customized machinery to meet your specific needs and applications.

Trusted Across Industries

Our clientele spans construction, mining, research laboratories, and other industrial sectors, both in India and internationally — a testament to our quality and reliability.

Sieve Shaker | Laboratory Pulverizer | Laboratory Mixer | Jaw Crusher

Our Clients Says

Certificates

Frequently Asked Questions

A laboratory Pulverizer is used in material testing labs to grind and crush samples into fine powder for accurate chemical and physical analysis.

You can buy a high-quality laboratory pulverizer online at LaboratoryJawCrusher.com, offering reliable models for various lab applications.

A laboratory jaw crusher is used to crush and reduce bulk materials into smaller sizes for sample preparation and analytical testing.

A laboratory jaw crusher works by using compressive force to break down hard samples between two jaws—one fixed and one moving.

A sieve shaker is used in laboratories to separate and classify particles based on size using mesh sieves.

A Laboratory Sieve Shaker works by vibrating or rotating stacked sieves to sort particles by size for accurate analysis.

A Laboratory Mixer is used to blend, homogenize, or emulsify samples for chemical, pharmaceutical, or materials testing.

A laboratory mixer uses rotational or oscillating motion to ensure uniform mixing of solids, liquids, or semi-solids during sample preparation.

A Polishing Machine is used to smooth and refine the surfaces of materials such as metals, ceramics, and samples for microscopic analysis.

A Laboratory Ball mill is used for grinding and mixing materials in scientific research, quality control, and material testing.