- +91-97119 86384

- +91- 85953 08916

- Pocket C, Plot No. 97, Sector 2, Bawana Industrial Area, New Delhi-110039, Delhi, India

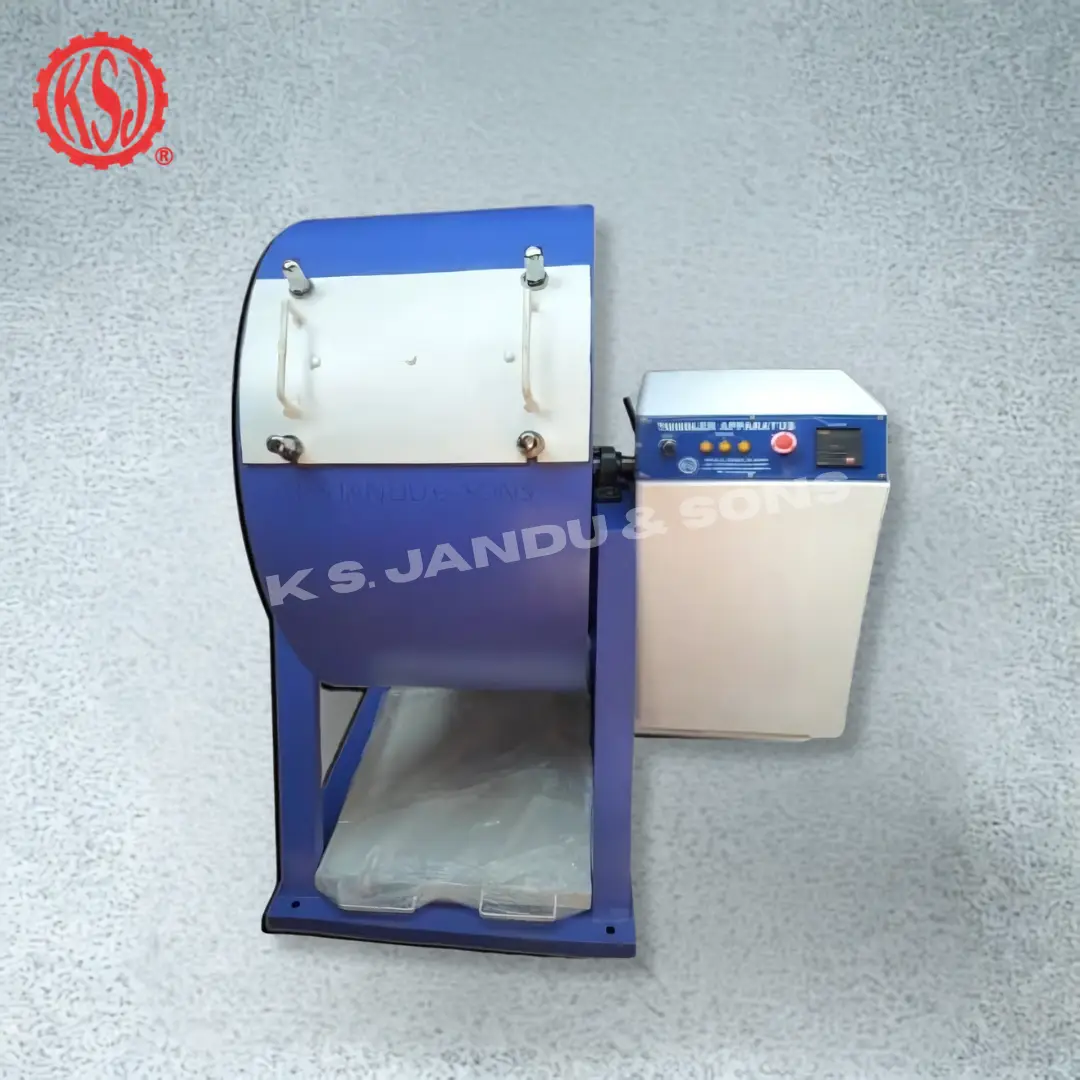

Tumbler Apparatus

| Specification | Details |

|---|---|

| Capacity | 100 kg/h |

| Usage/Application | Laboratory |

| Material | Mild Steel |

| Automation Grade | Semi-Automatic |

| Power | 440 V |

| Phase | Three Phase |

| Frequency | 50 to 60 Hz |

| Weight | 85 Kg |

| Brand | KSJ |

| Power Consumption | 1 Hp |

| Chamber Size | 200 x 75 mm |

Get a Quote

Product Overview of Tumbler Apparatus

- KS Jandu & Sons, a trusted Laboratory Jaw Crusher Manufacturer, presents the Tumbler Apparatus, designed for efficient grinding, mixing, and abrasion testing of laboratory samples. This apparatus ensures consistent and reproducible results for R&D, quality control, and educational laboratory applications.

- Developed by a leading Laboratory Jaw Crusher Manufacturer, the Tumbler Apparatus combines robust construction with semi-automatic operation, improving workflow efficiency and minimizing manual intervention.

- As a professional Laboratory Jaw Crusher Manufacturer, KS Jandu & Sons ensures this equipment meets stringent standards for durability, operational safety, and laboratory performance, making it essential for material testing labs.

Technical Specifications of Tumbler Apparatus

- Capacity: 100 kg/h, supplied by a trusted Laboratory Jaw Crusher Manufacturer, enabling efficient processing of samples with precision and reproducibility.

- Usage/Application: Laboratory testing and sample processing, developed by a professional Laboratory Jaw Crusher Manufacturer, ensuring accurate results for various laboratory procedures.

- Material: Mild Steel (MS), manufactured by a leading Laboratory Jaw Crusher Manufacturer, offering durability, stability, and long-lasting performance.

- Automation Grade: Semi-Automatic, supplied by a trusted Laboratory Jaw Crusher Manufacturer, providing controlled operation for reproducible laboratory testing.

- Power: 440 V, developed by a professional Laboratory Jaw Crusher Manufacturer, optimized for reliable and efficient operation in laboratory environments.

- Phase: Three Phase, manufactured by a leading Laboratory Jaw Crusher Manufacturer, ensuring stable electrical supply for precise operation.

- Frequency: 50 to 60 Hz, supplied by a trusted Laboratory Jaw Crusher Manufacturer, compatible with standard laboratory electrical systems.

- Weight: 85 Kg, developed by a professional Laboratory Jaw Crusher Manufacturer, providing stability and safe operation during laboratory procedures.

- Brand: KSJ, manufactured by a leading Laboratory Jaw Crusher Manufacturer, representing high-quality, reliable laboratory equipment.

- Power Consumption: 1 Hp, supplied by a trusted Laboratory Jaw Crusher Manufacturer, providing sufficient energy for effective operation without excess power use.

- Chamber Size: 200 x 75 mm, developed by a professional Laboratory Jaw Crusher Manufacturer, allowing optimal sample processing with uniform results.

Additional Features of Tumbler Apparatus

- Semi-Automatic Operation: KS Jandu & Sons, a trusted Laboratory Jaw Crusher Manufacturer, equips the apparatus with semi-automatic controls for precise and reproducible testing cycles.

- Durable Mild Steel Construction: Developed by a professional Laboratory Jaw Crusher Manufacturer, the apparatus withstands repeated laboratory use while maintaining accuracy and stability.

- Stable and Safe Operation: As a leading Laboratory Jaw Crusher Manufacturer, KS Jandu & Sons ensures minimal vibration and safe operation for laboratory personnel.

- Compact and User-Friendly Design: KS Jandu & Sons, a reputed Laboratory Jaw Crusher Manufacturer, designs the apparatus for easy installation, operation, and maintenance in laboratory environments.

- High-Precision Sample Processing: Developed by a professional Laboratory Jaw Crusher Manufacturer, the Tumbler Apparatus delivers consistent, uniform results for a wide range of laboratory applications.

Applications of Tumbler Apparatus

- Ideal for laboratory grinding, mixing, and abrasion testing, supplied by a trusted Laboratory Jaw Crusher Manufacturer for precise and reproducible results.

- Suitable for research, quality control, and educational laboratories, developed by a professional Laboratory Jaw Crusher Manufacturer, ensuring accurate and reliable laboratory testing.

- Perfect for R&D, industrial, and material testing laboratories, provided by a leading Laboratory Jaw Crusher Manufacturer, delivering consistent and uniform sample processing.

- Useful in laboratories requiring precise and controlled sample processing, manufactured by a reputed Laboratory Jaw Crusher Manufacturer, combining durability, efficiency, and operational precision.

Why Choose KS Jandu & Sons as a Laboratory Jaw Crusher Manufacturer

- KS Jandu & Sons, a leading Laboratory Jaw Crusher Manufacturer, delivers high-quality Tumbler Apparatus built for precision, durability, and reliable laboratory performance.

- As a trusted Laboratory Jaw Crusher Manufacturer, we ensure reproducible results, operational safety, and long-term reliability for all laboratory processing applications.

- KS Jandu & Sons, a professional Laboratory Jaw Crusher Manufacturer, provides expert guidance, customized solutions, and excellent after-sales support to meet diverse laboratory requirements.

- With decades of experience as a reputed Laboratory Jaw Crusher Manufacturer, KS Jandu & Sons guarantees timely delivery, superior quality, and complete customer satisfaction for all laboratory apparatus.